Archives

now browsing by author

Enhance Surfaces with Vibrant Colors Using Heat Transfer Powder Coating: An All-Purpose Solution

Heat transfer powder coating, also known as sublimation powder coating, is a cutting-edge method that enhances the appearance and functionality of different surfaces. This article provides an overview of heat transfer powder coating, its process, and highlights its unique features compared to traditional powder coating methods. Heat Transfer Powder Coating:Heat transfer powder coating involves applying a decorative coating onto a substrate using heat and pressure. Unlike traditional powder coating, it enables the transfer of intricate designs and vibrant colors ontoRead More …

Reclaiming Powder Coating: Unlocking the Potential of Reused Powder

With the rising demand for sustainable practices, industries are seeking ways to minimize waste and maximize resource utilization. In the realm of powder coating, the concept of powder reclamation has emerged as a viable solution. In this article, we explore the potential of recycled powder in the powder coating industry, emphasizing its benefits and considerations. 1. Embracing Powder Reclamation:– Industries are increasingly recognizing the value of reusing excess or oversprayed powder coatings, which reduces waste and cuts costs.– Efficient powderRead More …

Powder Coating: A Cutting-Edge Solution for the Construction Sector

Powder coating has emerged as a highly sought-after coating material within the construction industry. As the focus on environmental preservation and sustainable development continues to grow, powder coating has quickly gained popularity due to its exceptional performance and environmentally friendly attributes. This article delves into the emerging applications and future prospects of powder coating in construction, elucidating why it has become the preferred coating solution for an increasing number of construction projects. Powder coating finds extensive use in various areasRead More …

Antimicrobial Powder Coatings: A Comprehensive Overview on Enhancing Surface Protection

As the demand for combating harmful bacteria, viruses, and other microorganisms continues to rise, antimicrobial powder coatings are swiftly gaining popularity across various industries. This advanced coating technology provides a unique solution to suppress the growth and transmission of pathogens on different surfaces. This article will delve into the key characteristics and advantages of antimicrobial powder coatings, their diverse applications, and their crucial role in maintaining a sanitary environment. Introduction to Antimicrobial Powder CoatingsAntimicrobial powder coatings are specialized coatings formulatedRead More …

The Best Choice for Enhancing Texture and Protection: Wheel Powder Coating Technology

Introduction to Wheel Powder Coating Spraying Technology Wheel powder coating spraying technology utilizes the principles of electrostatic adsorption to evenly apply a fine solid powder coating onto the wheel’s surface. When subjected to high temperatures, the powder coating melts and forms a robust protective film. Advantages of Wheel Powder Coating Spraying Technology Improved Durability: Powder coating grants exceptional wear resistance to the wheel surface, allowing it to withstand the challenges presented by harsh road and weather conditions for an extendedRead More …

Enhanced Protection with High Temperature Powder Coatings: Conquer Coating Challenges in Extreme Heat Environments

Shielding surfaces from intense heat, oxidation, and corrosive elements becomes paramount in high temperature environments. To address this need, the innovation of high temperature resistant powder coatings emerged. This comprehensive article delves into the distinctive characteristics and merits of high temperature resistant powder coatings, along with their diverse applications across industries, offering effective solutions for coating predicaments in high temperature settings. Discovering High Temperature Resistant Powder Coatings High temperature resistant powder coatings are specifically formulated coatings tailored for environments withRead More …

How to Select the Perfect Powder Coating: Tips and Factors to Consider

When it comes to picking the ideal powder coating, it’s crucial to understand some key tips and factors to ensure you make the right choice. This article aims to guide you in selecting the appropriate powder coating that suits your specific needs and requirements. Material Type Consideration: Different surfaces require specific types of powder coatings. Whether you’re dealing with metal, plastic, wood, or other materials, it’s important to choose a powder coating that is compatible with and provides properRead More …

Comparing Powder Coating and Wet Paint:Pros and Cons

When it comes to paint options, powder coating and wet paint are two common choices. While they have many differences in practical application, they each have their own advantages and disadvantages. Powder coating is a solid-state paint composed of fine powdered particles that are typically applied to surfaces through electrostatic powder spraying. It offers excellent durability, maintaining color and appearance for long periods of time in both indoor and outdoor environments. Additionally, powder coating is a relatively simple andRead More …

Powder Coating Takes the Lead: Exploring Its Wide Range of Applications

Nowadays, powder coating is widely used and applicable in a variety of fields, far beyond traditional industrial coatings. Its high quality, efficiency and eco-friendly features make powder coating a preferred choice in many applications. Here are some detailed applications of powder coating in different industries: Automotive Industry: Powder coating is increasingly common in the automotive industry. With its unique resistance to wear and tear, as well as rich colors, powder coatings are used for car body paint, aluminum alloyRead More …

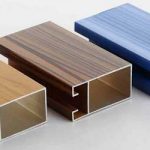

Advantages of Wood-grain Powder Coatings for Sustainable and Attractive Designs

Today, there is an increasing demand for wooden furniture. Although solid wood, wood composites, and artificial boards all occupy a certain market share, some consumers with enhanced environmental awareness are turning to new, more environmentally friendly and sustainable materials. This is where wood-grain powder coatings come in – a type of surface coating with a wood-grain effect, widely used in furniture, architectural doors and windows and other wooden accessories. Let’s take a closer look at the advantages and usage detailsRead More …

D5 Creation

D5 Creation