Uses of corona and tribo charging technology

Understanding the differences between corona and tribo charging, assists in deciding which technology is best for an application. Each type of charging has typically been used for specific industries.

Tribo charging has typically been used in industries which require epoxy powder or products that

have intricate shapes. Insulating products such as electrical equipment that only require protective coating are prime users of tribo charging guns. This protective coating is generally;epoxy due to its tough finish. Also, industries such as wire mesh products, airfoil grills,and radiators are often users of tribo because of the difficult shapes to coat. Tribo charging is capable of coating the intricate comers of many of these parts because an ion field is not present to cause the faraday cage effect or back ionization issues seen with heavy film thickness.

Corona charging has been used in industries where many types of powder are used, where quicker;conveyor speeds are required, and where specific film thickness control is required. Custom coaters use corona guns because of the need for flexibility with different types of powders and the quick color change time. Many industries such as outdoor products and decorative products use corona not only because of the type of powder required but also because of conveyor speed.

Conveyors running product at speeds greater than twelve to fifteen feet per minute generally require corona guns in order to coat the product at a reasonable capital investment expense;More tribo guns are required to coat products on conveyors operating at higher speeds. Corona guns can apply powder at high line speeds due to the higher powder output capability, the ion field charging, and wrap capability of the powder particles. Other industries such as appliance and automotive products require very specific film control requirements. Corona charging is capable of doing this at low and high powder output levels and over extended periods of time.

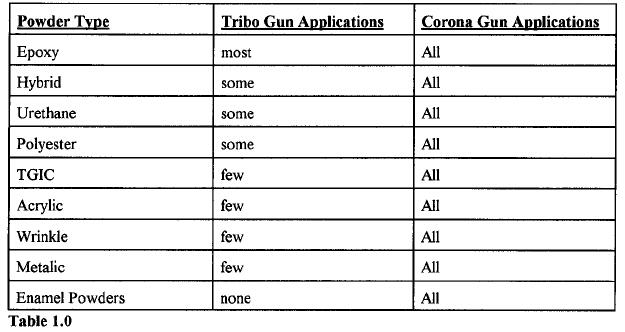

Different types of powder are used with the two technologies. Table 1.0 shows list of different powder types and the type of applicator that can apply it.

Powder manufacturers are capable of developing powder formulations for many different coating requirements. If there is an application that could be used with either tribo or corona guns, discuss the coating requirements with the powder manufacturer and the equipment supplier to achieve the best results.

[ Thanks for Michael J.Thies, please contact us if any doubt ]

D5 Creation

D5 Creation

Comments are Closed