Quality Control

- Technicians closely monitor each production cycle.

- Batch to batch reproducibility is always achieved.

- Regularly strict testing process ensures the quality.

- Sophisticated testing equipments ensure the quality of each batch.

Testing Process

Production Regular Spot Checking

Coating Thickness Test

Particle Size Distribution Test

Gloss Test

Adhesion Test

Impact Test

-

Production Regular Spot Checking

In production process, we conduct a regular spot checking batch to batch, to monitor each production cycle. This ensure the quality consistent and stable batch to batch. -

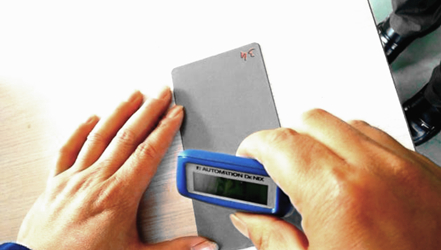

Coating Thickness Test

Thickness test ensure a proper coating thickness to get a suitable finish and texture. -

Particle Size Distribution Test

Proper powder particle size ensure a good finish, proper leveling property, spraying ratio and recovery ratio. This test ensure a consistent quality. -

Gloss Test

GLOSS TEST (ASTM D523) - Test coated flat panel with Gardener 60 degree meter. Coating shall not vary + or - 5% from data sheet requirements on each material supplied. -

Adhesion Test

CROSS HATCH ADHESION TEST (ASTM D3359) - Apply any sticky tape then remove slowly, results is no lifting of the cured powder between scribe lines. -

Impact Test

IMPACT TEST (ASTM D2794) - No grazing or loss of adhesion, finish is not able to be removed at impact area with 3M Y-9239 tape.

Certificate/Test Report

Certificate/Test Report Exhibition

Exhibition Factory Profile

Factory Profile Packing

Packing Production Workshop

Production Workshop Quality Control

Quality Control D5 Creation

D5 Creation