Powder Coating Method

Powder Coating Application Method

The method chosen to apply powder coating is varied depending on the specific part.Fortunately powder coating technology offers many choices in the applicatioin process.

Application methods available include Fluidized bed,Electrostatic Fluidized Bed,Electrostatic Spray(Corona Charging), Electrostatic Spray(Tribo Charging),and other methods such as flocking,electrostatic disc,tunnel coaster,flame spray,plasma spray.

For choosing a suitable coating method several factors should be considered: 1.The film thickness requirements; 2.Line speed; 3.Part configuration/size/thickness; and 4.Products performance characteristics.

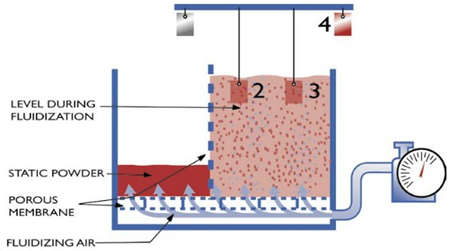

Fluidized Bed Coating

The fluided bed process is used for coatings between 254-400um with the final thicknss dependent upon part temperature and dip time in the powder.The film can be applied in thickness from 200-3170um.This process requires pre-heat temperatures of at least 180C and may require a post-heat or cure cycle. Typical uses for buss bars,transformers,fabricated wire,metal furniture,raceways,etc.

Process Steps : 1.Part pre-heated to 200-230C ; 2.Initial deposit melts onto part ;3.Film builds from residual heat ;4.Coated part with desired film

ADVANTAGES

- Uniform coating and product rreliability

- Complex parts 100%coverage

- Good process control and thick coatings

- Good edge coverage

DISADVANTAGES

- Pre-heat and post-heat ovens are required

- Minimum of 200um to be applied

- Complex shapes trap excess powder

- Thinner substrates donot hold heat,hard to coat

- Large heavy parts must be manipulated into bed

Links To: Electrostatic Fluidized Bed Electrostatic Spray(Corona Charging) Electrostatic Spray(Tribo Charging)

D5 Creation

D5 Creation